Machining

Hanke’s Custom Services matches their years of experience and creativity with reliable, traditional machine tools to achieve a superior result on your project.

Machining requires attention to a multitude of details in order for a work piece to meet precise specifications. Besides correct dimensions, attention must be paid to achieving the correct finish.

Machine Shop features include lathes, drill presses, milling machines, surface grinder, and band saws to perform turning, drilling, boring, milling, grinding, broaching and sawing operations all under the experienced, creative hand of Brian Hanke.

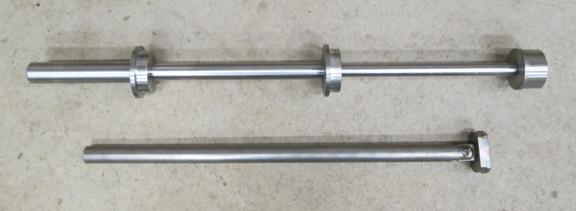

Machining Case Study: International Harvester Cam Shaft Bearing Installation Tool

Problem

Custom Bearing Removal and Installation Tools

As bearings wore out inside the camshaft of this tractor, it was very difficult to remove the worn out bearings and install new bearings.

Solution

Brian designed a custom bearing installation tool with a guide that stops the tool in the correct position. He also designed a custom bearing removal tool with a pivot feature.

Benefit

Because of these custom tools, bearing removal and replacement is easier and faster, minimizing downtime.

Contact Hanke’s Custom Services to discuss your machining needs. You will receive expert advice, cost estimates, and quick scheduling.